Shao Dong Yap

Pork CRC PhD candidate, Advanced Water Management Centre, University of Queensland.

Supervisor: Dr Stephan Tait, University of Queensland.

Solid progress on manure management

Shao Dong Yap’s research, conducted under Pork CRC Project 4C-111, ‘Anaerobic treatment for emissions reduction from solid manure residues’, focuses on minimising the greenhouse gas (GHG) emission from spent litter handling on-farm. The project is co-funded by Department of Agriculture.

Nutrient rich spent litter is typically stockpiled for composting before land application. Key concerns with this handling are uncontrolled GHG emissions, pest propagation, odour and nutrient leaching.

Spent litter

One of the more sustainable treatment processes for spent litter is anaerobic digestion, which offers significant advantages over conventional stockpiling, including renewable generation and nutrient recovery. The biogas outputs provide financial incentive for adoption by reducing on-farm energy costs and further reducing GHG emission by displacing fossil fuel derived energy. For instance, a 1000 pig deep litter system can produce up to 777 kWh per day of electricity. Given that energy costs have considerably increased in recent years, anaerobic digestion will likely enable pork producers to be more immune to future energy cost pressures. Further, anaerobic digestion also enables nutrient recovery to produce nutrient fertiliser or compost for off-farm sale, which is another financial incentive.

Several commercially successful anaerobic technologies have been developed for treatment of high solid waste (particularly municipal solid waste, but less so agro-industrial waste). However, farm-scale uptake of these technologies has been stifled by technical complexity and high investment cost.

Solid phase

The solid phase leachbed system (also known as percolation or batch digester) has been identified as a potential anaerobic technology for on-farm treatment of solid manure residue, as it is simpler and cost-effective compared to technology alternatives. In a leachbed process, a bed of spent litter is contacted with water leachate that allows biology to solubilise organics, nitrogen and phosphorus. The organics are then converted into biogas and nutrients are recovered. The water leachate is constantly recirculated through the leachbed system by trickling or flood-and-drain cycle to promote the rate and extent of spent litter degradation.

Shao profile

Shao’s Pork CRC research project will study the performance of leachbed for treatment of spent litter and develop ways to integrate this technology for on-farm use. A pilot study to assess the suitability of the leachbed system for treating spent litter has been conducted.

Shao is a Chemical Engineering graduate (with Honours) from The University of Melbourne (2010) and before his PhD research he worked at RMIT in Melbourne as a research assistant studying rheological (viscosity/flow) behaviour of polymer gel and colloidal suspensions as model fluids representing anaerobic digestion sludge. Shao started work at the AWMC in 2012 when he established a pilot-scale test rig of anaerobic digestion (using a membrane bioreactor) and nutrient recovery (using struvite) in the meat processing industry. During this time, Shao successfully designed, partly built, commissioned and operated the pilot scale equipment at an abattoir in Queensland. This hands-on experience was invaluable, preparing Shao for his current PhD project which also involves hands-on technology testing.

Shao’s broader research interest/skills include rheology (complex viscosity), anaerobic digestion and co-digestion, biogas use and nutrient recovery from wastes, integrated waste treatment, bioreactor design/control, plus commissioning and operating pilot facilities.

Further information: Shao Dong Yap

www.porkcrc.com.au

First published in APN July 2015

Dr Sergi Astals-Garcia

Postdoctoral Research Fellow, Advanced Water Management Centre, The University of Queensland.

Projects 4C-105/109/111

Advancing carbon neutral pork production

Sergi Astals-Garcia is a postdoctoral research fellow at the Advanced Water Management Centre (AWMC) at The University of Queensland and is involved in several projects within Sub Program 4C – Carbon-Neutral Pork Production.

Dr Astals-Garcia obtained his Bachelor in Chemical Engineering and Master in Science in Environmental Engineering at The University of Barcelona (Spain) and then in June, 2013 The University of Barcelona awarded him his PhD, which was devoted to the anaerobic co-digestion of agro-industrial wastes.

Through these years at the Environmental Biotechnology research group of The University of Barcelona, Dr Astals-Garcia participated in several projects (RE-WISE, BIOGAS ACCEPTED, PROBIOGAS, NOVEDAR Consolider, RECUMOR+) and consultancies with industrial partners. In October 2013 he commenced as Post-doctoral Research Fellow at The University of Queensland, where his research mainly focuses on anaerobic digestion, a technology able to transform organic waste to energy.

Anaerobic digestion

Anaerobic digestion (AD) is a biochemical process which, in the absence of oxygen, decomposes organic matter into biogas and a digestate. The methane content of biogas is an important source of renewable energy (electricity and/or heat), making anaerobic digesters a treatment technology that produces energy instead of consuming it, while digestate is a stabilised product that can be used as fertiliser or soil conditioner. Nevertheless, digesters’ design, operation and performance, as well as process drawbacks, are strongly linked to the nature/origin of the organic residue.

Feasible farming

As part of 4C-111: Developing anaerobic digestion and nutrient recovery technology for spent piggery litter aims to provide a feasible on-farm alternative for solid manure residues stockpiling, which is responsible for greenhouse gas emissions and water contamination, among others. However, spent litter physical (i.e. lignocellulosic bedding mixed with faeces, urine, spilt feed and water from drinkers) and production (i.e. waste exiting the shed in large batches) characteristics, makes it difficult to apply conventional AD configurations. The configuration chosen to treat spent litter is batch AD (also known as solid-phase AD), a system where waste is filled in the digester, retained for a period of time and emptied. Due to its operational and reactor simplicity, batch AD systems are starting to be applied to treat municipal solid waste of medium-size cities and crop wastes (less common). The applicability of batch systems for crop wastes is limited by two main factors: (i) hydrolysis rate (i.e. speed of particulate matter solubilisation), and (ii) the presence of inhibitors. The latter is especially relevant for pig spent litter, where high ammonia concentrations are expected due to pig faeces and urine. On the other hand, such limitations can be overcome by adapting digester operational conditions and/or including additional processes to minimise the impact of such compounds. The AWMC research group is now evaluating which is the best operational strategy for a batch AD treating spent litter and how operational conditions impact digester biogas yield and the presence of potential inhibitions in the system, especially ammonia and propionic acid.

Inhibiting factors

The presence of an inhibitor in the digestion medium is one of the main reasons behind AD low yields/failure. There are many substances (e.g. ammonia, sodium, heavy metals, antibiotics) that at a certain concentration can inhibit anaerobic biomass, especially methanogens (responsible of methane production). Surprisingly, despite the importance of quantifying inhibitory potential of compounds in anaerobic digestion, there was no well-defined method to assess it. 4C-105: Assessing stimulation and inhibition of anaerobic lagoons allowed to develop and validate simple and rapid method to identify and quantify the inhibition capacity of a specific compound on methanogens (Application no. 2014903895). The patented method can be used to quickly (three days after inoculum collection) determine the inhibitory potential of a specific compound for a particular anaerobic biomass. Inhibition testing is of utmost importance since it can contribute to process understanding, risk assessment and decision making. For example, inhibition testing can be used in decision making about upstream process changes to minimise impact on digester performance, the use of one or another antibiotic or other disinfectant in a piggery, co-substrate selection and dose and chemical pre-treatment dosing. Related to inhibition, in the undergoing 4C-109: Enhanced methane production from pig manure in covered lagoons and digesters, we are performing a pioneering project which combines inhibition testing, continuous AD monitoring data and microbial community analysis to determine if anaerobic biomass acclimatisation is due to adaptations of the key organisms or changes in community profiles.

Finally, it is worth mentioning our last publication on anaerobic digestion Anaerobic co-digestion of pig manure and algae: Impact of intracellular algal products recovery on co-digestion performance, in which experimental results were used to assess a high-level concept for an integrated biorefinery processing pig manure and algae growth on-site using supernatant from digested pig manure.

Please do not hesitate to contact Dr Sergi Astals-Garcia (s.astals@awmc.uq.edu.au) if you require more information about waste anaerobic digestion, as well as our research activities at the Advanced Water Management Centre.

First published in APN Feb 2015

Jeremy Ayre

Pork CRC PhD candidate in Project 4A-106, Growth, development and use of algae grown on untreated and undiluted anaerobic digestion piggery effluent, Murdoch University, WA.

Principal Supervisor: Dr Navid Moheimani, Murdoch University.

Ayre to algae throne

Jeremy Ayre completed his Honours in Biotechnology at Murdoch University in 2013 on a Pork CRC supported project which considered the use of microalgae as a component of piggery wastewater treatment.

Currently anaerobic digestion is widely used by in piggeries for wastewater treatment. Piggery anaerobic digestate is very high in ammonium concentration, turbidity and pH. Jeremy’s project looked closely at tackling some of the hurdles presented when considering algae treatment of the anaerobic digestion effluent including the freshwater use to dilute the algae treatment.

The focus of his studies was performing a proof-of-concept demonstration that explored the hypothesis that it was possible to grow algae successfully with undiluted effluent at very high ammonia levels, usually considered toxic to algae. At the first stage, he spent a few months isolating suitable algae. Reliable cultivation of isolated species was the next step. He used raceway ponds at the Murdoch University Algae R&D Centre and was able to grow the isolated algae successfully over the course of several months and in a production-style semi-continuous system for approximately five weeks, limited by the completion of his Honours year.

PhD platform

As far as the current literature reports, growth of algae in such high ammonia levels has not previously been demonstrated. Publication of the data and outcomes from this study is planned for the end of 2014 and these findings open the way for further research in optimising the growth of the algae, aiming at integration into piggery wastewater treatment systems. The positive outcomes have also led to further interest in Pork CRC supporting continuation of this work with a PhD project following on from the initial study.

Integration of algae treatment into piggery wastewater is not a new concept, with research in this area dating back to the 1970s.There is a novel approach here which might make algae wastewater treatment a reality for piggeries. By focusing only on using undiluted anaerobic digestion effluent Jeremy believes there is great potential to make this highly applicable to Australian piggeries as we are not adding any further freshwater to the system.Coupled with high solar radiation and suitable algae growth conditions in Australia, particularly WA, further development of this technology would hopefully lead to economic benefits, as well as further improvement of the environmental footprint sometimes associated with pig production.

Optimisation strategies

Although currently in the early planning phase of the PhD, there is a reasonably distinct course ahead which follows on directly from the work achieved in the Honours project. The PhD project will look at optimisation strategies to enhance the growth and consistency of algae production. It will also consider the nutritional composition and potential benefits of using the algae biomass as a supplement to the pig diet.

Jeremy is also interested in looking at furthering anaerobic digestion of the carbon-enriched algae biomass. The potential exists to enhance biogas production of the piggery, which, along with the primary anaerobic digestion process, should allow capture and reuse of a large part of the piggery greenhouse gas emissions. Not only does the biogas provide a fuel source for use at the piggery for purposes such as heating or electricity production, the carbon dioxide output from combustion of the biogas fuel also might serve as an algae growth accelerator. Some supporting results in the honours project and current algae literature suggests significant enhancement of algae growth using the carbon dioxide rich gas. The end outcome may also intrinsicallylead tothe creation of clean fresh water which can be used again by the piggery.

Harnessing waste

Overall, Jeremy hopes to explore and develop a system whereby a waste product in the form of piggery wastewater can be harnessed into a resource for piggeries. The piggery waste itself, which hassignificant nutrient levels, can cause problems as a potential pollutant, however he is hoping to reuse this waste in generating a potential pig feed and/or fuel source and outputting clean treated fresh water by use of algae treatment to overcome the limitations of such a high ammonia environment. Environmentally friendly considerations also potentially see the use of sustainable energy in the form of sunlight and consuming greenhouse gasses which might otherwise be output into the environment.

Support network

Jeremy feels fortunate that he is able to conduct his PhD with support from Pork CRC and Murdoch University, where he appreciates very good supervisory support, including Dr Navid Moheimani (pictured below, also with Program 4 Leader, Dr Rob Wilson) as principal supervisor overseeing the project and especially the algae growth, optimisation and limits to the growth, Professor John Pluske, Murdoch University, helping with the nutrition aspects, Dr Sasha Jenkins, UWA, helping with the anaerobic digestion and Emeritus Professor Michael Borowtizka, Murdoch University, helping with a vast knowledge in algal cultivation and economics. The project is also supported by the Department of Agriculture and Food, Western Australia (DAFWA) and University of Melbourne.

Contact: Jeremy Ayre, email jmailbox@gmail.com

Pork CRC Student Feature APN Oct 2014

Giang Nguyen

PhD topic: Influence of particle size and size distribution of cereals and pulses on digestibility and growth performance of pigs

Giang Nguyen: Pork CRC PhD candidate, Queensland Alliance for Agriculture and Food Innovation, University of Queensland.

Principal Advisor: Dr Peter Sopade

Giang attack on grain particle size

Giang holds a BSc degree in Animal Husbandry and Veterinary Medicine from the Cantho University, Vietnam, and MSc in Agricultural Science from the Swedish University of Agricultural Science, majoring in nutrition for non-ruminants. She is an AusAID scholar, and a PhD student at the University of Queensland, under Dr Peter Sopade’s Pork CRC project 4B-112.

Milling matters

In Australia, pig feed is based mainly on grains that supply the bulk of the nutrients to pigs. Field pea (Pisum sativum L.), a pulse and sorghum (Sorghum bicolor), a cereal, are commonly used and subjected to various combinations of unit operations and/or processes to make their nutrients available. Milling is usually the first feed manufacturing operation, with hammer, roller, and disc milling, as the main ones. Milling reduces grain particle size, and differences in grain fracturability lead to particle size distribution. There are also grain-to-grain fracturability differences, plus mill differences. Within a mill, particle size and particle size distribution can vary as mill settings change, hence, grain and mill differences can generate a variety of particle sizes and distributions, which affect feed efficiency. Previous Pork CRC studies at University of Queensland revealed that feed digestibility can be substantially reduced with an increase in feed particle size. There appears to be an optimum particle size for each grain and this is yet to be defined in combined laboratory and animal studies. Giang’s research aims to establish this optimum size, using an innovative process engineering approach to understand the disappearance of starch and protein in pig diets during passage through the gastrointestinal tract. In view of their importance in the Australian pig industry, Giang’s PhD concentrates on field peas and sorghum and includes these objectives:

– Influence of disc and hammer milling conditions on particle size and size distribution of the grains and how they affect starch and protein digestion, feed conversion and growth performance.

– Status of starch and protein in diets with different particle sizes at the ileum using cannulated pigs.

– Flow regimes of different particle-sized grains in the pig gastrointestinal tract, using residence time and exit age distribution concepts to predict the critical particle size for complete ileal digestibility based on diffusion rates of amylases and proteases.

Studies started

Giang’s research is broadly divided into two tasks: (a) laboratory studies using in-vitro techniques developed in previous Pork CRC projects and (b) animal studies with the relevant Pork CRC commercial partners. The key element of her research is using commercial samples and set-ups to ‘represent real life situations’.

The research started by obtaining two field pea varieties (Maki and Walana) from Pork CRC and these were disc and hammer milled with different settings under laboratory conditions to vary their particle sizes and distributions. Roller milling was also investigated, but at one level. The in-vitro starch and protein digestibility of the milled field peas was studied and, using a modified first order kinetic equation, the rates of starch and protein digestion were obtained to examine the particle size effects in a typical pulse and relative digestibility of starch and protein in the pulse, with implications for nutrient asynchrony. There were mill differences in the digestibility of the pulse, with the hammer-milled field peas showing higher digestibility due to its higher thermo-mechanical effects.

There were no significant variety effects and with Walana the preferred variety by the pig industry, it was used for a weaner feeding study at a Pork CRC commercial partner. Walana was disc and hammer milled in commercial mills to reflect the industrial set-up for adoption of the research. The diets were formulated to meet the nutrition requirements of weaner pigs, with the field peas being about 30%. The trial did not reveal particle size differences in animal performance and it could be because the field peas were ground within the optimum particle size of the pulse. Giang’s research is investigating this further to guide the particle size range for acceptable milling of the pulse. How sorghum affects animal performance of weaner pigs is ongoing.

Future studies

The gastrointestinal tract can be likened to a pipe with complex flow regimes, as the feed moves through the small intestine. Differences in particle size can influence mixing and flow in the tract, with possible differential transport of starch and protein. Giang’s research will establish, among other things, if:

(a) Larger particles arrive at the ileum before smaller particles and carry more starch and protein.

(b) Particles, which arrive first at the ileum, irrespective of particle size, contain more starch and protein.

(c) The time course of appearance of milled feed particles at the ileum can be modelled using an engineering pipe flow approach.

(d) Animal digestibility reconciles sufficiently with in-vitro digestion data to provide a quantitative prediction of critical particle size for complete ileal digestibility.

To achieve this, a pig cannulation experiment planned before the end of the year will use mash diets from field peas and sorghum that will be disc and hammer milled to different particle sizes.

Industry benefits

Blending laboratory with commercial situations is a major plus in Giang’s research, as it establishes milling as an important feed manufacturing operation. The research has already established differences in milled grains for pig feed and the need to control milling, towards maximising energy delivery from pig diets. Her research evaluated a manual sieving device developed in a previous CRC project and demonstrated how valuable the device is for Australian feedmills. Ultimately, the research will establish optimum particle sizes for the selected pulse and cereal, to guide how grains should be economically milled for maximum feed efficiency in pigs.

Contact Giang Nguyen, email t.nguyen61@uq.edu.au

Ryan Cheng

Ngai Ning (Ryan) Cheng, Pork CRC PhD candidate, School of the Environment, Flinders University, South Australia

PhD Topic – Exploitation of wastewater grown microalgae for the production of biogas and feedstocks

Supervisor: Prof Howard Fallowfield, Flinders University

Positive exploitation of wastewater

Ryan Cheng has a Bachelor of Medical Science with majors in microbiology, neuroscience and physiology and a Bachelor of Science (Hons), both from South Australia’s Flinders University, where he is now a Pork CRC supported PhD candidate.

CRC studies

Anaerobic digestion, which is a well established process for treating many types of solid and liquid organic wastes, is often used to reduce the mass of solids and pathogen load and produce energy in the form of methane gas.

Increasingly, covered anaerobic lagoons are being considered by the pork industry to manage greenhouse gas (GHG) emissions and recover the methane for energy production.

Algal biomass produced in high rate algal ponds (HRAP) treating piggery wastewater removes CO2, contributing to GHG mitigation and is an additional source of biomass energy which could be released via co-digestion with pig slurry.

While other wastes, such as industrial organic wastes, fruit and vegetable solid waste and olive wastes and farm wastes, are commonly co-digested, there are limited studies on the digestion of algal biomass as a sole substrate or co-digested with other wastes such as pig slurry. Batch anaerobic co-digestion experiments were performed to study the effect of algae addition on the co-digestibility of pig slurry.

Ryan’s Pork CRC PhD study program has two essential research areas to determine:

- The impact on algal growth of CO2 addition to wastewaters of varying organic carbon – this research is largely completed (Stage 1)

- The factors influencing the anaerobic co-digestion of algal biomass with pig slurry.

This project builds on the outcomes of Pork CRC Project 4A-101 ‘Algae for Energy & Feed: a wastewater solution’ which reviewed options for the industry to integrate algal biomass production for energy and feed into pig slurry treatment.

Manure handling

Currently, the overwhelming majority of pork producers use lagoon systems for wastewater treatment. A small minority of producers have covered anaerobic lagoons to reduce emissions of the GHG methane from slurry. The life cycle assessment (LCA) analysis indicates that rather than ‘flaring’ this renewable energy source, the industry should be encouraged to exploit biogas for water or space heating or in combined heat and power systems thereby reducing fossil fuel usage and associated GHG emissions. To achieve this, the review investigated a large range of advanced manure handling strategies. Only those strategies with real prospects of successful integration on-farm have been recommended for further study. Specifically the review recommends the integration of controlled, closed vessel aerobic treatment (with heat recovery), followed by solids separation to enable microalgal growth on anaerobic digester effluent. The LCA indicates that further wastewater treatment by microalgae, followed by additional energy recovery via co-digestion of the algal biomass with pig slurry is the option most likely to achieve the Pork CRC aspirational GHG emission target of 1kg CO2e kg HSCW-1 by 5% of the Australian pork industry. Further, this strategy will enable research on the subsequent production of microalgae for pig feed, post-wastewater treatment, potentially facilitating better management of the microalgal growth environment and control of species and nutritional content.

Manure Energy

There are two ways of obtaining energy from manure: aerobic or anaerobic treatment. During the breakdown of organic material by aeration, heat is produced by aerobic bacteria, which can be recovered with the aid of heat exchangers and /or a heat pump.

Perhaps of more significance is that ammonia, an inhibitor of algal growth, can be oxidised to non-toxic nitrate by aerobic treatment. During anaerobic fermentation the complex organic matter is degraded to the relatively clean and easily purified gaseous products carbon dioxide and methane, which may be collected from covered anaerobic lagoons or from engineered digesters. There are three options for the biogas utilisation:

- Flaring (if there is no need or infrastructure to produce steam or electricity)

- Substituting gas for existing LPG/NG (i.e. boiler)

- Generating electricity

For power generation units, the gas is usually fed into methane-powered engines that generate electricity. The waste heat, a by-product of generating electricity, can be used to heat other industrial processes (covered lagoons, space heating, etc).

After anaerobic treatment, there is still a large amount of nutrients (nitrogen and phosphate, in particular) in solution, leaving the possibility of recycling nutrients from the liquid phase, along with CO2 from the biogas, through a High Rate Algal Pond (HRAP) and using the biomass for further energy production via digestion. The renewable energy generated by this photosynthetic process, offsets fossil fuel usage and reduces GHG emissions by the industry.

Expected outcomes

– Determination of the effect of CO2 addition on the growth of algae on wastewater effluent from an anaerobic lagoon. This information will inform decisions regarding the infrastructure required at core facilities to conduct research on the growth of algae for fuel and feed.

– An understanding of the optimum conditions for co-digestion of wastewater grown algal biomass with pig slurry, which will include determination of the effect of feed ratios and digester residence time on the quantity and quality of biogas produced and suspended solids/COD removed.

– Determination of the effect of proximate composition of algal biomass on the biogas yield and quality.

– Data on biogas yield and quality for use in subsequent life cycle assessments to determine sustainability and GHG abatement of integrating algal wastewater treatment with co-digestion of the biomass with pig slurry.

Pork CRC Program 4 (‘Carbon conscious nutrient inputs and outputs’) conducts research to improve the sustainability of the pork industry within Australia, specifically, to reduce greenhouse gas emissions to about 1 kg CO2 equivalent/kg pork produced for 5% of the industry by 2015. Pork CRC Project 4A-101 ‘Algae for Energy & Feed: a wastewater solution’ has identified that one of the most promising means of meeting this target is to integrate the treatment of piggery wastewaters in covered anaerobic lagoons or in engineered anaerobic digesters (with biogas production and/or electricity generation) with algal biomass production to recycle CO2 and provide additional biomass for energy production.

Industry benefits

The research proposed here will contribute to industry by:

- Resolving the infrastructure required to adopt the technology by determining whether external CO2 addition is beneficial to algal growth on anaerobically pre-treated piggery slurry. This will assist industry in assessing the costs associated with the proposed technology.

- Identifying the operating parameters (ratio slurry: algal biomass feed and anaerobic digestion retention time) for efficient co-digestion of slurry and algae for biogas production and wastewater treatment. This will, hopefully, contribute significantly to the target reduction in GHG emissions through pork production.

- Enabling construction of research/demonstration scale facilities at selected pork producer sites to showcase and encourage uptake of the technology by the industry.

Contact Ryan Cheng, email ryan.cheng@flinders.edu.au

First printed in APN Feb 2014

Megan Hawley

PhD Topic – Advanced integrated treatment of pig slurry for algal biomass production and improved pig health

Supervisor: Prof Howard Fallowfield, School of the Environment, Flinders University, South Australia

Waste not want not

Megan Hawley recently commenced a PhD project, co-funded by the Pork CRC as part of Pork CRC Program 4 (Carbon conscious nutrient inputs and outputs), in the School of the Environment at Flinders University, SA. She has a Bachelor of Science degree in microbiology and molecular biology and an Honours degree in environmental health. Her research aimed to improve the assessment of the risk to human health associated with consumption of wastewater-irrigated lettuce.

About algae According to Megan, Australia’ pork industry is actively looking to reduce its environmental impact, particularly associated with greenhouse gas emissions. Her project is in response to the recommendation of the Pork CRC commissioned review ‘Algae for Energy & Feed: a wastewater solution’, which recommended research into the integrated treatment of piggery slurry, including investigation of the potential for algae to further treat the wastewater and as a source of biomass for energy production. The majority of Australian piggeries dispose of wastewater in deep ponds, which operate with anaerobic bacteria to produce a biogas, which is rich in methane. Some piggeries harvest this biogas and flare off the methane component. A very few piggeries use the methane in co-generators to produce electricity. Anaerobic ponds accumulate ammonia and retain significant pathogen levels. This water is frequently reused as flushing water within the piggery, which may result in adverse health effects to exposed pigs, reducing growth rates and increasing feed costs. Further, at high pH the ammonia prevents the growth of algae on the pig slurry.

CRC project Megan’s project will investigate the first stage of an integrated approach to wastewater treatment to remove the ammonia and pathogens and enable subsequent algal growth on piggery wastewater. Aerobic treatment has been found to be an effective removal strategy, capable of oxidising ammonia to a non-toxic form of nitrate. Further, the metabolic energy produced by naturally occurring bacteria treating the waste can be recovered and may be used around the farm as hot water to be used for such things as replacing the electrical energy used in heat pads. Since anaerobic digestion plays a key role in current piggery treatment strategies, Megan’s project will investigate the integration of anaerobic processes with aerobic treatment and high rate algal ponds for the removal of ammonia, pathogenic organisms and energy production.

Slurry solution The project, which aims to examine aerobic treatment of pig slurry from an anaerobic pond to enable successful algal growth on treated effluent, links into a larger project run by Flinders University in SA, which is looking to generate heat, energy and quality wash water from integrated aerobic and algal treated pig slurry to help the industry reduce environmental impacts. A laboratory scaled aerobic reactor will be used throughout the research. Chemical and microbial analyses will be performed on slurry treated in the laboratory scaled aerobic reactor to assess the ammonia removal and pathogen reduction potential of the integrated treatment train under a range of experimental conditions.

Integrated treatment Results from this study will help evaluate an integrated treatment system for the disinfection of piggery slurry, which could lead to its use in piggeries around Australia. It will provide valuable information regarding the optimal conditions needed to assist and run an on-farm scaled system, enhance wastewater quality for reuse in pig sheds, reduce production costs and enable algal biomass production for energy as part of the larger project run in South Australia.

Contact Megan Hawley, email hawl0006@flinders.edu.au

First printed in APN Feb 2014

Alan Skerman

Masters’ Topic: Low-cost options for biogas energy use on-farm at piggeries

Masters’ Topic: Low-cost options for biogas energy use on-farm at piggeries

Supervisors: Dr Stephan Tait, University of Queensland and Stephan Heubeck, NIWA, NZ.

Alan Skerman is working on a Master of Philosophy degree through the University of Queensland (UQ) Advanced Water Management Centre (AWMC), in collaboration with the National Institute of Water and Atmospheric research (NIWA), New Zealand. His research topic is conducted under the Pork CRC’s Subprogram 4C – Carbon-Neutral Pork Production, is ‘Low-cost options for biogas energy use on-farm at piggeries’. Interest in the collection, treatment and use of biogas has increased across the Australian pork industry in recent years, driven mainly by the significant potential to reduce energy costs and carbon emissions from individual piggeries and the industry as a whole. Further financial incentives, such as the Carbon Farming Initiative (CFI), have also added to the interest.

Major obstacles One of the major obstacles to the widespread adoption of biogas technology is the presence of relatively high concentrations of hydrogen sulphide (H2S), generally ranging from 500 to 3000 ppm, in the raw biogas collected from covered anaerobic ponds and engineered digesters. The corrosive, odorous and toxic nature of the H2S can limit the life of appliances such as engines used to drive generators to produce electricity and boilers used to heat water for circulation through farrowing sheds, while potentially threatening the health of humans and livestock.

Novel options Alan’s research project seeks to identify and properly characterise novel and low-cost biogas purification options for on-farm use. Identifying and describing suitable purification media will help farmers better utilise biogas resources, protect equipment using biogas and make biogas utilisation safer and more profitable. Increased ease and profitability of biogas use will accelerate uptake of biogas technology, enhancing pork production sustainability, while reducing production costs, throughout Australia and NZ. Uptake will be further enhanced by focusing on substrates and technology currently available and which may be used without IP limitations. Alan’s proposed research will:

- Identify up to five low-cost, ‘alternative’ biogas purification media (waste and by-products)

- Estimate their availability and likely price

- Determine their ability to purify biogas under controlled conditions

- Identify how these materials may be incorporated into a biogas capture and use system

- Estimate their efficacy relative to commercially available substrates

- Guide appropriate handling of promising alternative biogas purification media under field conditions.

Alan is a Principal Environmental Engineer employed by the Department of Agriculture, Fisheries and Forestry (Queensland), which is providing significant in-kind support for this project. He previously successfully led several APL research projects, investigating improved effluent management technologies and the validation and development of the PigBal model. Alan also recently completed three additional research projects under the Australian Methane to Markets in Agriculture (AM2MA) program, trialling piggery biogas collection, treatment and use technologies at a commercial piggery in southern Queensland. This work has provided Alan with considerable relevant experience leading into his current Masters project. Alan is currently a member of APL’s Specialist Group 5 (environmental management) and the Pork CRC Biogas Support Program Steering Committee.

Contact details: Alan Skerman, Email alan.skerman@daff.qld.gov.au First printed in APN Sept 2013

Jing Hooi Tan

Bachelor of Biomedical Science (B BioMedSc) Honours Project – Kinetics of starch and protein digestion in cereals and pulses with special reference to field peas – University of Queensland Supervisor: Dr Peter Sopade Jing’s Pork CRC Honors project falls under project 4B-112: Optimising particle size distribution for grains and protein sources which aims to optimise particle size distribution in grains for maximum digestibility and energy delivery from pig feeds.

Bachelor of Biomedical Science (B BioMedSc) Honours Project – Kinetics of starch and protein digestion in cereals and pulses with special reference to field peas – University of Queensland Supervisor: Dr Peter Sopade Jing’s Pork CRC Honors project falls under project 4B-112: Optimising particle size distribution for grains and protein sources which aims to optimise particle size distribution in grains for maximum digestibility and energy delivery from pig feeds.

Grains picked Cereals and pulses are used in pig feeds as starch and protein sources. In order to understand the diversity, Jing selected 15 genotypes of field peas (Pisum sativum), wheat (Triticum spp.), barley (Hordeum vulgare L.), and lupins (Lupinus L.). The field pea varieties included Maki and Walana, both commonly used in Australian pig feeds. These grains will be ground in different mills to vary their particle sizes. In the Australian pig industry, hammer, disc and roller mills are the commonest mills, according to a recent survey. Differences in the predominant milling force will influence the particle size distributions and, consequently, average particle size. Depending on mill settings, it’s possible to obtain fine or coarse sizes. Worth noting is that grain genotypes play a role in particle size distribution of milled grains.

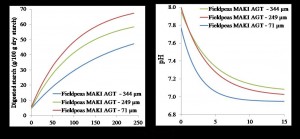

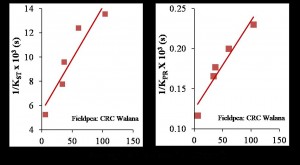

Digesting energy Jing’s project targets the digestion of starch and proteins, as the main energy yielding components in grains. In-vitro starch and protein digestion procedures have been developed in earlier Pork CRC projects using α-amylase, pepsin, pancreatin, and amyloglucosidase in a glucometry method for starch and trypsin, chymotrypsin and protease in a pH drop method for proteins. Being time-course procedures, the kinetics of starch and protein digestion can be investigated and the digestion rate of these major components obtained. Jing will be using these procedures in my project to specifically obtain rates of starch and protein digestion in the grains and to relate these to particle size of the milled grains. His results have shown monophasic starch and protein digestograms, irrespective of the grain and particle size (see Fig.1). Fine samples were generally more digested than coarse. For the rates of starch and protein digestion, Jing applied a modified first-order kinetic model to the data to obtain rates of starch and protein digestion and it suitably described the digestograms.

Figure 1

Relating rates of starch and protein digestion to particle size revealed that a two-fold increase in particle size can result in a four-fold decrease in digestion rates (see Fig.2). This can translate to significant loss in animal performance and revenue. There are also differences in starch and protein digestion which are valuable in understanding asynchrony of nutrients for energy and growth. When Jing’s project is completed, he should be able to comment on the relative digestibility of these major nutrients. However, his findings to date emphasise the importance of particle size and show that in pig feeds, size matters!

Figure 2

Size control When Jing completes his project, he will fully demonstrate the need for the pig industry to control and monitor particle size during milling of cereals and pulses in feed manufacture. A parallel project under Project 4B-112 is field testing a manual sieving device with its user friendly spreadsheet, which will prove useful in quality control of grain milling for pig feeds.

Future direction As a Biomedical Science student, Jing believes it’s been a worthwhile experience, finding how milling, which is the first major operation in the feed manufacturing chain, can exercise so much influence on animal performance. His project concentrates on in-vitro procedures, and the bigger project (Project 4B-112) will understand how this particle size-digestibility relationship applies in animal studies. The data obtained will be useful to feed manufacturers, and the broader pig industry.

Contact details: Jing Hooi Tan, Email jing.tan1@uqconnect.edu.au First printed in APN Dec 2012